Topaz Tangaroa:

challenging project, brilliant result

Five Cat engines, two ports, one coronavirus

COMPLETE REVISION

A challenging job, in several locations

"During the work, some damage to the camshafts of the two C32s on board was discovered. "Pon Power repaired this damage under warranty, so the project was not delayed," says Frederik Sorhaug. Adding with satisfaction: "All in all, the team just delivered really good work. A challenging job, in several locations, subject to all the coronavirus restrictions and with some unforeseen additional work. And all within planning and budget. In short, a job well done!"

FACTS &

FIGURES

overhaul tight and compact

Using Cat guidelines (re-use and salvage guidelines), we established the state of wear parts and only replaced parts if that was strictly necessary, to keep the overhaul as tight and compact as possible. However, the situation was complicated because the ship needed to be mobilised during the work. Destination: Rotterdam. There we continued a top-end overhaul of the C3512.

logistic puzzle

Challenge number two, the different locations of the ship, mainly created a logistic puzzle. Aarssen explains: "The work started in Harlingen, where we began with the overhaul of the two C3516s. We serviced the cylinder heads and turbo chargers in our own 5-star platinum

workplace in Papendrecht. We overhauled all the components for this job. This meant that nothing needed to be shipped to the US, which meant an enormous reduction in CO2 emissions in this project. Additionally, this resulted in significant cost savings.

CORONAVIRUS

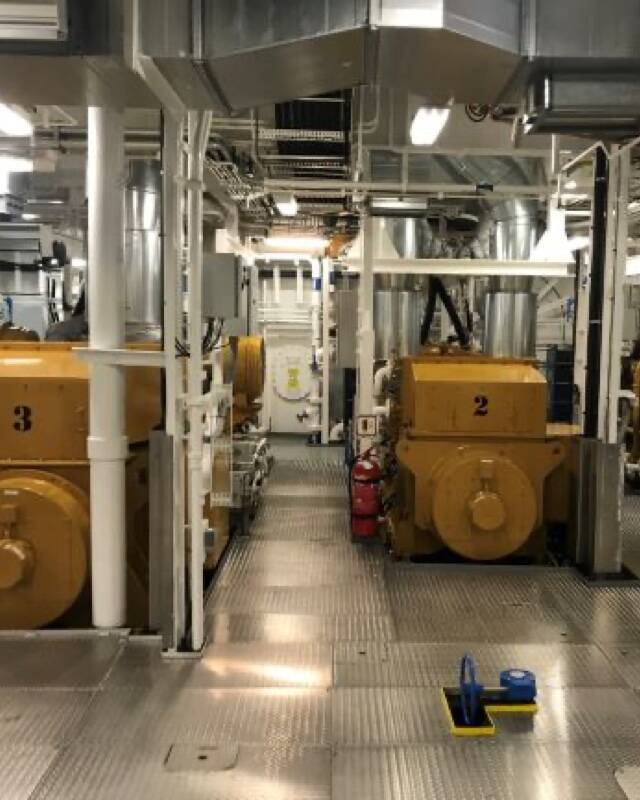

Now that might sound relatively straightforward, but the project involved various issues. Such as the coronavirus, which was raging through the country at the time, creating issues for personal safety. Furthermore, the Tangaroa needed to be in different Dutch ports during the standby window. This produced an interesting puzzle. Jan Aarssen, Account Manager Product Support at Pon Power, explains: "To start with coronavirus: at Pon Power, we have a strict safety protocol. That requires engineers to work in set pairs, always keeping a distance and not coming in direct contact with the crew of the ship. That protocol was stringently followed on the Tangaroa too. During the work, our engineers Werner Schipper and Pascal Soonius lived and worked in their own bubble, completely apart from the crew. Fortunately, the Tangaroa has a hyper modern, spacious engine room, so there was no problem maintaining social distancing."

JAN AARSSEN

Accountmanager Product Support

Pon Power

"Our engineers lived and worked in their own bubble, completely separated from the crew"

OFFSHORE CONSTRUCTION VESSEL

The Topaz Tangaroa is an impressive ship. Everything about the 98-metre-long ship breathes heavy-duty functionality, not least because of the helipad which is located just above the bridge on the bow. And that word heavy duty also applies to the use of the Tangaroa. The ship was delivered in 2019 and has since been almost constantly in operation.

Fredrik Sorhaug, Fleet Superintendent Subsea at P&O Maritime Logistics/Topaz Energy and Maritime Limited explains: “The Tangaroa is an offshore construction vessel. On board, it has an arsenal of tools and equipment for repairs, maintenance and underwater investigation. Since its delivery, the Tangaroa has been in use 24/7, 365 days a year, so the engines were ready for an overhaul. We decided to use the standby window, the winter, for this."

FREDRIK SORHAUG

Fleet Superintendent Subsea

P&O Maritime Logistics/Topaz Energy

"Pon Power repaired this damage under warranty, so the project was not delayed"

Every technical job is different. Sometimes a simple routine job can create enormous problems. At other times, an extensive and challenging project can go extremely smoothly. This was the case for the work on the engines of the Topaz Tangaroa. Motorennieuws investigated.

Topaz Tangaroa:

challenging project, brilliant result

Five Cat engines, two ports, one coronavirus

COMPLETE REVISION

"Our engineers lived and worked in their own bubble, completely separated from the crew"

Accountmanager Product Support

Pon Power

JAN AARSSEN

CORONAVIRUS

Now that might sound relatively straightforward, but the project involved various issues. Such as the coronavirus, which was raging through the country at the time, creating issues for personal safety. Furthermore, the Tangaroa needed to be in different Dutch ports during the standby window. This produced an interesting puzzle. Jan Aarssen, Account Manager Product Support at Pon Power, explains: "To start with coronavirus: at Pon Power, we have a strict safety protocol. That requires engineers to work in set pairs, always keeping a distance and not coming in direct contact with the crew of the ship. That protocol was stringently followed on the Tangaroa too. During the work, our engineers Werner Schipper and Pascal Soonius lived and worked in their own bubble, completely apart from the crew. Fortunately, the Tangaroa has a hyper modern, spacious engine room, so there was no problem maintaining social distancing."

logistic puzzle

Challenge number two, the different locations of the ship, mainly created a logistic puzzle. Aarssen explains: "The work started in Harlingen, where we began with the overhaul of the two C3516s. We serviced the cylinder heads and turbo chargers in our own 5-star platinum workplace in Papendrecht. We overhauled all the components for this job. This meant that nothing needed to be shipped to the US, which meant an enormous reduction in CO2 emissions in this project. Additionally, this resulted in significant cost savings.

"Pon Power repaired this damage under warranty, so the project was not delayed"

Fleet Superintendent Subsea

P&O Maritime Logistics/Topaz Energy

FREDRIK SORHAUG

A challenging job, in several locations

"During the work, some damage to the camshafts of the two C32s on board was discovered. "Pon Power repaired this damage under warranty, so the project was not delayed," says Frederik Sorhaug. Adding with satisfaction: "All in all, the team just delivered really good work. A challenging job, in several locations, subject to all the coronavirus restrictions and with some unforeseen additional work. And all within planning and budget. In short, a job well done!"

overhaul tight and compact

Using Cat guidelines (re-use and salvage guidelines), we established the state of wear parts and only replaced parts if that was strictly necessary, to keep the overhaul as tight and compact as possible. However, the situation was complicated because the ship needed to be mobilised during the work. Destination: Rotterdam. There we continued a top-end overhaul of the C3512.

FACTS & FIGURES

SHIP:

Topaz Tangaroa

SHIPPING COMPANY:

P&O Maritime Logistics / Topaz Energy and Marine Limited (Noorwegen)

APPLICATION:

Offshore Supply Vessel

TONNAGE:

6133

DIMENSIONS:

98,1 x 20,05 meter

MOTORISATION:

2 x 3516, 1 x 3512, 2 x C32

Every technical job is different. Sometimes a simple routine job can create enormous problems. At other times, an extensive and challenging project can go extremely smoothly. This was the case for the work on the engines of the Topaz Tangaroa. Motorennieuws investigated.

OFFSHORE CONSTRUCTION VESSEL

The Topaz Tangaroa is an impressive ship. Everything about the 98-metre-long ship breathes heavy-duty functionality, not least because of the helipad which is located just above the bridge on the bow. And that word heavy duty also applies to the use of the Tangaroa. The ship was delivered in 2019 and has since been almost constantly in operation.

Fredrik Sorhaug, Fleet Superintendent Subsea at P&O Maritime Logistics/Topaz Energy and Maritime Limited explains: “The Tangaroa is an offshore construction vessel. On board, it has an arsenal of tools and equipment for repairs, maintenance and underwater investigation. Since its delivery, the Tangaroa has been in use 24/7, 365 days a year, so the engines were ready for an overhaul. We decided to use the standby window, the winter, for this."